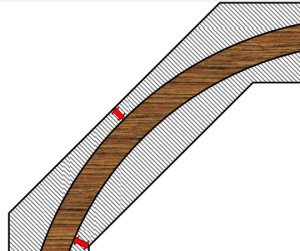

Interested in turning segmented projects on the lathe? You’ll need to know a few things about each ring you want to include in your project in order to make sure that they line up properly with the rings directly and below.

There are several software packages for both computers and smart devices which will assist you with all the calculations required to help ensure that each of the segments in each ring are of the proper length and angles so they fit together snugly and provide good glue surfaces.

In my day-to-day life, I depend heavily on technology and am glad for the tools developed to make that all happen. Woodworking however is a hobby and I enjoy the process as much as the final outcome, so picking through the tools and resources I already have appeals to my need to fiddle with stuff along the way. Your mileage may vary 🙂

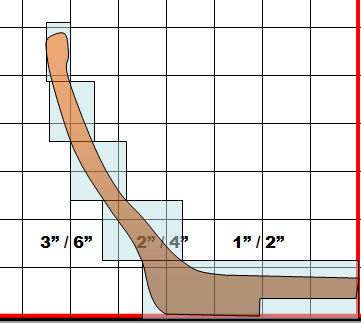

Start with a profile drawing of your bowl or vessel, this will provide a cross section of what the wall will look like and give you a way to size the dimensions properly. YouTube creator Alan Stratton (As Wood Turns) showed a nifty way of using PowerPoint to create this. Below is a simple drawing based on that idea.

You could also use graph paper to produce the same results. The blue boxes represent a profile view of the turned portion of the ring. This is the important bit! The width of each segment piece needs to be large enough to span from the smallest inside diameter to the largest outside diameter.

You also want to include some fudge factor when making calculations for cutting segments. This will include a little bit of extra wood to correct for subtle alignment challenges when stacking rings during glue-up as well as adding a little space to allow for mild design modifications during turning.

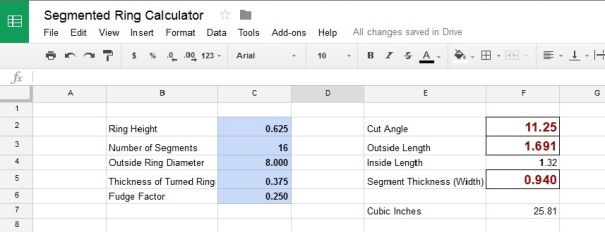

Here is the link to the calculator

It is a spreadsheet in Open Document format. You’ll need to download this file to use it as DropBox only allows a preview. If you are a Gmail user, upload it directly to your Google Drive, or alternately it can be opened with recent versions of Microsoft Excel.

Segmented Ring Calculator.ods

To use it, enter known values into the blue shaded area:

- Ring Height

- Number of Segments for the ring

- Outside Diameter (Final turned measurement)

- Thickness of Turned Ring (Max OD to Min ID)

- Fudge Factor — This value will be added onto both inside and outside dimensions to calculate the wood segment size required.

As you update values, the calculations shown in red show the width and length of each segment, along with the angle to be cut at each end.

Another handy value returned is the volume in cubic inches for that ring. This is based on the innermost minimum diameter. A ring with a slanted inner wall will actually hold just a little tiny bit more. As a side note for creating cremation urns, one cubic inch of volume is recommended for each pound the final occupant weighed before cremation.

Good advice!